Categories

- Additional Insured

- ChildrensProducts

- Claims Made

- Cyber Insurance

- Dietary Supplements and Nutraceuticals

- Ecigarettes

- Firearms Insurance

- Food Products

- Foreign Products Liability

- Foreseeable Misuse

- Frivolous Lawsuits

- General Liability

- Industrial

- Infographics

- Intellectual Property

- Looking ahead

- Marijuana Liability

- Medical Products

- Mutual Indemnification

- Nano Technology

- News

- Online Sellers Insurance Requirements

- Outsourcing

- Piercing The Corporate Veil

- Pollution Liability

- Product liability

- Product Recall

- Retail Chain Store

- Start-Up Business

- Statute of Repose

- Surplus Lines Insurance

- Technology

Advances in 3D bioprinters

Progress in medical technology mean better quality of life

“Hey, Doc, I need a tune-up.”

This may be a common request doctors receive from athletes and arthritic patients in the near future.

What is a 3D bioprinter?

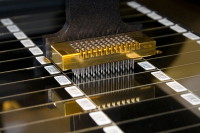

3D bioprinters essentially print human tissue on a printer similar to the ones we use in our homes and businesses. Instead of paper-feed mechanisms, these printers feed slides or other supporting porous materials, such as polymers. The ink is replaced with stem cells, which are printed directly onto the slides or materials.

A chemical inserted during the printing stage allows the cells to be programmed to become cartilage, bone cells, etc.

Where we are and where we’re going

Current advances in cartilage constructs allow them to be implanted to regrow cartilage in the joints. Combining synthetic materials ensures the strength of the construct. Adding natural gel materials provides an environment that promotes cell growth. These also create durable, implantable constructs that will integrate into the surrounding body tissue.

In the future, cartilage constructs will be clinically applied by using an MRI scan of the injured body part, such as a knee, and creating a matching construct. Once implanted with the hybrid system of durable synthetic materials and stem cells, the implant should withstand mechanical forces while encouraging new cartilage to organize and fill the defect.

What does this have to do with Product Liability insurance?

Nothing! But it’s exciting news for the potential in improved quality of life for us aging baby boomers.

Posted By: Paul L. Owens-

Click the Button Below to Get Your

Click the Button Below to Get Your

No-Obligation Quotes from Among the

Top 18 Leading Insurance Carriers Today -

Recent Industry News

- How to Prevent Nuclear Product Liability Verdicts

- Amazon Sellers and Vendors Strategy Including Insurance Requirements

- Walmart Sellers Insurance

- Product Liability Limit Requirements of Online Sellers

- State-by-State Product Liability Analysis of Laws Impacting Businesses

- Children’s Product Liability: Strange Claims and Need for Insurance

- Product Liability vs. Environmental Insurance for the Chemical Industry

- Product Liability in the 3D Printing Industry: New Materials and Their Significance

- Product Liability Concerns in Agricultural Equipment Enhanced with Artificial Intelligence

- Navigate Product Liability in Battery and Solar Industry

Monthly News Archives